Roller Shutter Doors

Whatever the size, finish or application of the roller shutter or high speed door, whether power operated or manual operation, we can generally offer a guide price proposal by return.

Commecial use shutters have relatively few opening activations every day and a single phase electric tube motor powered roller shutter is likely to be the most cost effective.

Industrial Application roller shutters with more intense usage require a heavier duty three phase motor with chain override.

Hand Chain Shutters are recommended when no power supply is available, use is infrequent or there may be risk of explosion if electric operation was used. Chain shutters consist essentially of a curtain of interlocking slats which form a continuous hinge along their entire length. This construction permits the curtain to roll up or down as it is raised or lowered onto a revolving spring loaded barrel which is mounted onto steel support brackets. A bottom rail fitted to the curtain strengthens the curtain and allows for the fitment of handles and locking devices. The curtain is also prevented from moving side-ways by side channels or guides. The entire assembly is either bolted or welded to the structure and the rolling mechanism can be enclosed in a canopy hood.

Architect’s Specification Sheet

Product reference:

MDS Industries Limited

COMMERCIAL ROLLER SHUTTER RANGE

Performance: Not applicable

Arrangement: Vertical roller shutter powered by single phase electric tube motor

Accreditation: BS EN 1324. Online Information http:// www.rollershutterdoors.com A commercial steel vertically operated roller shutter available with either solid punched or perforated curtain.

Dimensions: Opening height up to 5000mm, opening width up to 8000mm. Shutter weight: 35 kg/m² of door opening.

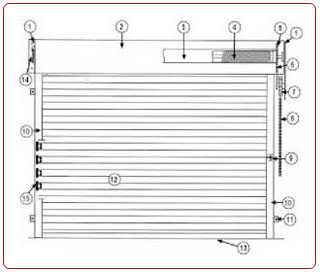

Curtain: Constructed from 75mm galvanized cold rolled scroll sections of suitable gauge, each alternate lath is fitted with a steel or nylon end lock to prevent lateral movement and wind anchor locks on larger doors.

Curtain Modification: Perforations 2 mm O/D Punching 150 mm w x 45 mm h Brick bond or Inline Punching 76 mm w x 45 mm h Brick bond or Inline

Bottom Rail: The base of the curtain is fitted with a steel angle reinforcing rail of adequate size forming an inverted ‘T’.

Side Guides: 90 x 34mm or 120mm x 34mm extruded aluminium guide with integral box section for strength.

Roller Assembly: Constructed from mild steel tube of sufficient gauge to prevent deflection, mounted on bright steel shafts running in ball races, reduction drive gearing where applicable is by machine cut steel gears or chain drive to suit the size of the opening.

Endplates: The roller assembly is supported by mild steel endplates with mounting angles for fixing to the support structure.

Roller Enclosure: (optional extra) Formed from galvanised pressed sheet metal to enclose the rear of the shutter barrel and curtain assembly.

Operation: 240 volt single phase Tube motor with low voltage toggle switch or key switch control and optional hand crank override.

Control Unit MDS Industries Safe Voltage Finish Galvanised and primed ready to paint, Or powder coated to any standard BS or RAL number

Manufacturer: MDS Industries Limited

OPTIONS

Controls and operation:

Key switch control unit – flush mounted

Key switch control unit – surface mounted

External weatherproof push button

Key lockable push button control

Group control unit for up to 6 shutters simultaneously

(will require additional safety edge)

Radio controlled (will require additional safety edge.)

Safety Systems:

Safety bottom edge

Safety photo cell beam

Security:

Ground locks and interlock facility

Bullet lock interlock box

Emergency operation:

External manual override for external fitted electric shutters.

External manual override lockable plate to crank hole.

External manual override for internal fitted electric shutters.

Internal manual override for internal fitted electric shutters

Battery back-up unit

Powder Coated Finishes: As an optional extra powder coated finishes can be provided to the shutter in standard RAL or BS standard colours as well as non-standard colours if samples are provided for us to analyse.

Warranty: We warranty all parts free from manufacturer’s defects for a period of twelve months from the commissioning date. The warranty also covers call out charges and fitting charges for replacement parts supplied under the warranty. The warranty does not cover repairs due to accidental damage or misuse, fair wear and tear or any loss of use while replacement parts are being supplied or fitted.

Architect’s Specification Sheet

The MDS Industries Single Skin Roller Shutter Door is designed, manufactured, installed and serviced by our own teams of engineers in operating conditions as diverse as St Helena in the South Atlantic to Kandahar in Afghanistan.

Curtain: The curtain material is generally constructed from individual inter-locking pre-galvanized steel lath (generally 75mm concave) incorporating either a plastic endlock or a zinc alloy die cast endlock riveted in position.

Bottom Rail: A pre-galvanized T bar is provided to connect onto the base of the curtain material.

Barrels: Constructed from mild steel tube with inner blocks, helical springs to BS970EN 498 in the case of a chain operated or assisted shutter. The sizes and types of spring are designed to accommodate the appropriate curtain weight. Where additional gearing is provided for operation this may consist of either spur gearing or chain drive.

Bracket: These are fabricated from mild steel plate fitted with mounting angles for securing to the opening structure. Where gearing is applicable spur gearing or chain drive will again be used, dependent upon the size of door. Normal operation through the gearing would be by means of an endless hand chain operated at floor level.

Side Guides: Formed in roller steel channel, wind anchor type, complete with suitable mounting angle where necessary. The depth and type of guide will be subject to the door size and location. Door guides are finished primed. Top Brush Seal: Fixed if specified off the client’s soffit to close the gap between the curtain face and the building line and consists of a heavy duty brush in an aluminum carrier.

Casings: As an option extra a pre-galvanized steel casing/soffit/fascia can be provided to the coil at the head of the opening. We would recommend casing where a door is fixed to the exterior face of the opening, likewise motor covers where electrical equipment is fixed outside and subject to the weather.

Power operation: An electric motor unit of suitable rating would be mounted at high level to the gear end of the bracket, the motor being complete with controlling limits, brake unit and emergency hand chain facility. A standard starter unit would also be provided with raise, lower and stop buttons. All electrical equipment would be to suit 380/415 volt 3 phase 50-cycles supply (singlephase equipment also available).

Plasticol Finishes: As an optional extra shutter curtains can be provided in the HP200 standard range of plasticol colours, plasticol finishes being to the external face of the shutter only. Standard colours include White, Black, Van Dyke Brown, Merlin Grey, Goose Wing Grey, Mushroom and Red.

Powder Coated Finishes: As an optional extra powder coated finishes can be provided to the shutter in standard RAL or BS standard colours as well as non-standard colours if samples are provided for us to analyse.

Activation Options: As our standard offering opening activation on electric shutters is “dead man down” operation, i.e. the operative needs to keep their finger on the button to lower the door. Various automated activation options are available, such as radar, remote control and floor laid vehicle detection loops. Each require the addition of safety beams and a safety bottom bar that can be supplied factory fitted.

Warranty: We warranty all parts free from manufacturer’s defects for a period of twelve months from the commissioning date. The warranty also covers call out charges and fitting charges for replacement parts supplied under the warranty. The warranty does not cover repairs due to accidental damage or misuse, fair wear and tear or any loss of use while replacement parts are being supplied or fitted.